- Stock: In Stock

- Model: DOEPFER-A-192-2

More from this brand

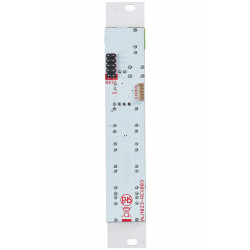

Module A-192-2 contains two independent CV/Gate-to-Midi/USB interfaces. For each of the two sub-units these inputs are available:

For both sub-units a common CV Transpose input is available (1V/octave, range 0...+10V). The voltage applied to this input is added internally to CVN before the Midi note number is generated. It can be used e.g. to transpose two sequences simultaneously by one voltage. How it works: Important note: The CV voltage has to be present at the rising edge of the gate signal. It seems that for some sequencers on the market that's not true. If a sequencer generates the CV after the rising edge of the gate the A-192-2 will output apparently wrong Midi data because an "old" CV is taken to generate the Midi data. But that's a problem of the sequencer, not the A-192-2. To fix this problem the A-192-2 would have to "wait" a couple of milliseconds (depending upon the delay between Gate and CV of the sequencer in question) before the CV is measured. But this would degrade the timing because then the Midi data are sent later then the rising edge of the gate signal. Please clarify if you want to use the A-192-2 with a sequencer if the CV/gate timing is correct (for the A-155 that applies of course). In Velocity mode the voltage applied to the CVV input is used to define the velocity data of the Midi note on message (in Volume mode a fixed velocity value 100 is used). As soon as the falling edge of the Gate input is recognized the corresponding Midi note off message is generated (i.e. with the same note number as the preceding Midi note on message). The voltages at the CVN and CV Transpose inputs during the falling edge of the Gate do not have an effect on the note number of the note off message ! In any case the note number of the preceding note on message is taken. Otherwise hanging Midi notes would occur ! Adjustment of the Conversion Parameters Example 1: 0V are applied to CVN (or the CVN socket is left open) and a Midi note message with note number 36 on Midi channel 1 is sent while the upper sub-unit of the module is in learn mode: then a CVN voltage of 0V corresponds to Midi note number 36 for the upper sub-unit and the data are sent on Midi channel 1. When a Midi control change message is received while the unit is in learn mode the control change number of the Midi message is taken for CVC (except CC#0 and CC#32 as these are reserved for Midi program bank change). Program change messages are used in learn mode to select the Volume mode (program change #0) or Velocity mode (program change #1). Pay attention that the Midi channel of the incomung control change or program change messages has to correspond to the Midi channel that is assigned to the A-192-2 sub-unit in question. In addition one can switch between the two modes without the need of a program change transmitter: for this one has to operate the learn button in question for several seconds. Then the LED starts to flash faster than in the learn mode and the other function for CVV (volume or velocity) is selected. But with this procedure one has no optical feedback which mode (volume or velocity) is selected. One simply is able to toggle between the two modes. But one can find out very simply which mode is selected because the module generates continuous Midi volume data only in the Volume mode. When a variable voltage applied to the CVV socket generates Midi volume data (without a Gate signal) the Volume mode is selected. Otherwise the Velocity mode is active. The data generated by the module are transmitted simultaneously to Midi Out and USB. Two or more A-192-2 modules can be daisy-chained via Midi Out - Midi In. Incoming Midi data is merged to the Midi output - provided that the incoming data volume is not too high (because of the limited Midi Input buffer of the module). A Midi keyboard or a second A-192-2 are no problem but please do not try to merge a fully loaded 16 channel sequencer track. The two LEDs also display the activity of the sub-units (i.e. if Midi data are generated by the unit in question). Factory settings:

The factory setting can be restored by operating the learn button of the corresponding sub-unit during power on (i.e. the button has to be held down while the A-100 system is turned ON). Typical applications:

| ||

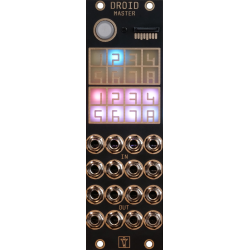

Breite/Width: 10 TE / 10 HP / 50.5 mm | ||

-285x169.png)